Wafer Level Packaging (WLP) is combining wafer manufacturing and device encapsulation technologies. WLP is a chip-scale-packaging technology where many IC's can be stacked together using suitable interconnect processes (like TSV or metal bumps) followed by encapsulation.

- A combination of visable and infrared illumination for multiple quality assessment tasks

- CD control

- Undercut measurement

- Residues inspection

Get in Touch

Reasons to Choose Muetec

Since decades we are listening to your manufacturing challenges and, together with you, find solutions to solve them successfully. You are invited to benefit from our accumulated know how that translates into tools, software algorithms and application support.

The installed base of our tools reaches from volume semiconductor manufacturers to mask shops and research institutes. We installed and service hundreds of tools all around the world. The satisfaction of our customers drives our motivation to exceed their expectations.

We are proud to provide the flexibility to adopt our solutions to your individual requirements. All of us at MueTec understand that one size does not fit all and we are proud of our ability to adopt to your special needs in a fast and competent fashion.

Our existing customers value the robustness of our tools, many of them being in use for 15 years or longer. All of our tools are designed and manufactured in Germany with highest quality standards.

Our Mission

MueTec serves the semiconductor equipment industry as well as a number of other, closely related industries. Our systems, services and software algorithms help nanoelectronics manufacturers manage yield and minimize waste throughout their manufacturing process, from research and development to final mass production.

- Cost-effective solutions

- Your metrology and inspection specialist

- Installed base of more than 250 systems

- Local service and maintenance from certified technicians

Best Solutions for Wafer Level Packaging

IRIS2100

200mm MEMS inspection and metrology system (open cassette)Show details

Typical Applications

MEMS Sealing Inspection

MEMS Device Inspection

Overlay/CD Metrology

Defect Review

Features

Best IR image quality

Flexible handling (backside vacuum, flipping, edge-vacuum) for MEMS specific wafers

Combined reflected & transmitted light illumination modes

SECS/GEM

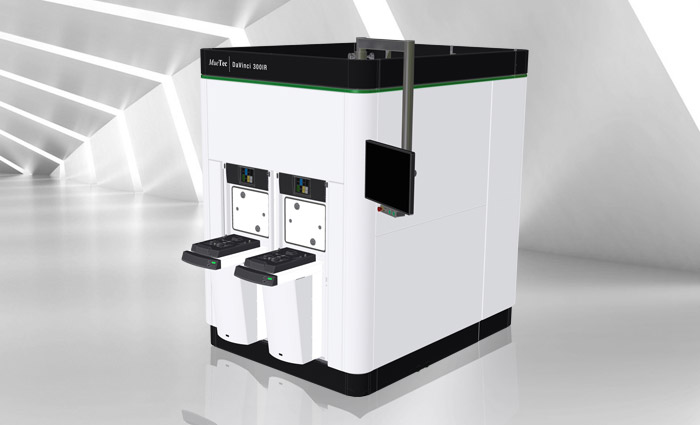

DaVinci 200IR + 300IR

200mm MEMS inspection and metrology system (SMIF)Show details

Typical Applications

Sealing Inspection after bonding

(eutectic bonding or glass frit bonding)

Device Inspection after bonding

Overlay Metrology after bonding

Critical Dimension Metrology after bonding

Features

Best inclassIR image quality with wafelengths of up to 1500nm

Flexible handling (backside vacuum, flipping, edge-vacuum) for MEMS specific wafers

Combined reflected & transmitted light illumination modes

SECS/GEM