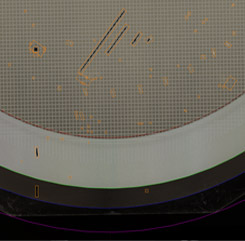

MueTec’s inspection solution for outgoing process control of the sawing process includes all areas of the framed wafer on foil. This includes the inspection of the sawing lines, as well as scratches, cracks, missing dies and particles.

The inspection algorithm follows the recipe-free approach of the Argos product family. Many different product types can be inspected without creating specific recipes.

Key Features

- 380 mm framed wafer FOUP based handling

- Optimized for multi-zone inspection of wafer, foil and frame. Detected defects include:

- Sawing line failures

- Cracks

- Scratches

- Bubbles in foil on frame and wafer

- Holes in foil

- Etc.

- Data acquisition perfectly balanced to mechanical movements

- Simultaneous brightfield and dark field inspection

No recipe required for ease of use:

- Enables productivity gains through minimum recipe customization

- Ideal for fabs and packaging areas with many different devices & die sizes

- No learning of alignment marks, chip size or wafer center necessary. Die layout data is not necessary

- Recognition of active die area and EBR zone

- Different sensitivities for different wafer areas

- Avoiding false positives at zone transitions

- Automatic adjustment of light intensity

- Reflectivity of inspected layer is not necessary

- Automatic defect recognition parameters by adaptive software algorithm

Products

Argos 300-F

Post-saw Framed Wafer InspectionShow details

The Argos 300-F product is optimized for post-saw inspection of framed wafer on foil. With a high throughput of 110 300mm wafer on a 380mm frame, the system inspects many different defect types, from sawing line failures to defects on the foil and on the frame.

Key Features:

380 mm framed wafer FOUP based handling

Optimized for multi-zone inspection of wafer, foil and frame.

Data acquisition perfectly balanced to mechanical movements

Simultaneous brightfield and dark field inspection

No recipe required for ease of use