DaVinci 270UV – Mask CD Metrology

MueTec's has a large, global installed base of optical CD (Critical Dimension) mask metrology systems. These systems were sold under the “LWM270UV” brand name by Leica and KLA in the past. The latest member of this product family is the DaVinci 270UV, a fully enclosed, fully automated mask metrology system.

DaVinci 270UV

Mask CD MetrologyShow details

Typical Applications

Critical Dimension Metrology

Features

Cost effective solution for mask layers with feature sizes of 300nm and above

UV and visable light capability

Reflected and transmitted light

Highest quality opticcs

Flexible tool configurations available

CD repeatability (3 sigma) long term < 4 nm (etched layer)

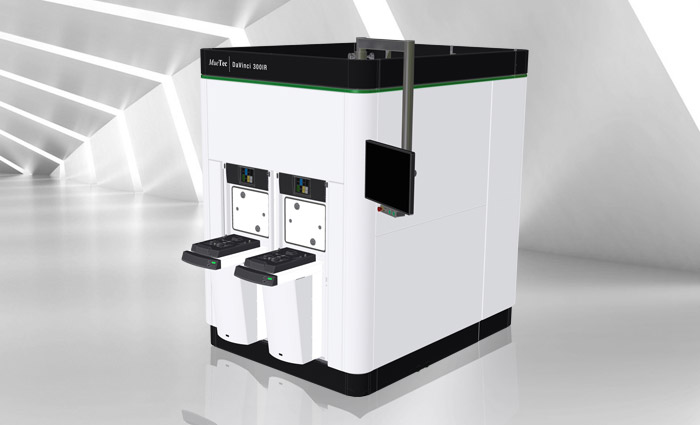

DaVinci 200IR, DaVinci 300IR – Infrared (IR) solutions for CD, Overaly and Inspection

MueTec's Infrared-Solutions are designed to improve manufacturing yield in MEMS manufacturing. We offer fully automated solutions for 100 mm, 150 mm, 200 mm and 300 mm MEMS wafer.

DaVinci 200IR + 300IR

200mm MEMS inspection and metrology system (SMIF)Show details

Typical Applications

Sealing Inspection after bonding

(eutectic bonding or glass frit bonding)

Device Inspection after bonding

Overlay Metrology after bonding

Critical Dimension Metrology after bonding

Features

Best inclassIR image quality with wafelengths of up to 1500nm

Flexible handling (backside vacuum, flipping, edge-vacuum) for MEMS specific wafers

Combined reflected & transmitted light illumination modes

SECS/GEM

MT3000 – Wafer Metrology

MT3000

Fully automated metrology and inspection system (open cassette)Show details

Typical Applications

CD

Overlay

Film Thickness

Defect Inspection

Defect Review

Features

VIS, UV

Simultaneous wafer handling 75 - 200mm

SECS/GEM