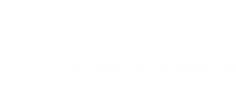

High Throuput Macro Defect Inspection

MueTec’s mask inspection is using a die-to-die approach to detect statistical failures on the mask. This tool is used to monitor the masks in wafer manufacturing, typically in power semiconductor, LED and MEMS manufacturing.

Our tool helps the customer to automatically decide if the photomask is good, requires cleaning or needs to be replaced.

Products

Spector

Automatic and fully enclosed with FFUShow details

Typical Application

Mask defect inspection

Key Features

Fully enclosed tool architecture

Robot handling of masks with up to 2 pod or cassette stations

Automatic inspection based on die-to-die comparison

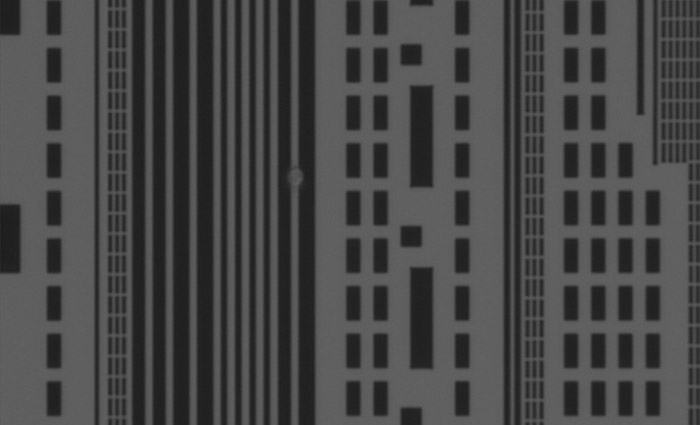

Resolution of 0,5 μ/pixel

Defect sizes as of 1 μm

Mask sizes up to 14’’

Spector A

Automatic with mask robot and mask carriersShow details

Typical Application

Mask defect inspection

Features

Open tool architecture

Robotor mask loading and unloading

Fully automatic mask inspection

Automatic inspection based on die-to-die comparison

Resolution as of 0,5 μ/pixel

Defect sizes as of 1 μm

Mask sizes up to 14’’

Spector M

Semi AutomaticShow details

Typical Application

Mask defect inspection

Features

Open tool architecture

Manual operator mask loading and unloading

Automatic inspection based on die-to-die comparison

Resolution as of 0,5 μ/pixel

Defect sizes as of 1 μm

Mask sizes up to 14’’