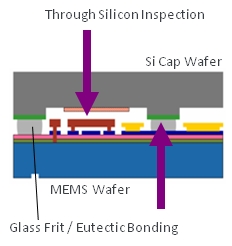

Silicon, GaAs wafers and other substrates become transparent at infrared (IR) wavelengths. High performance IR optics in combination with a high efficiency InGaAs camera provide images with superior resolution and contrast.

Advantages of MueTec solutions

- The optics are designed and optimized for the IR range from 1050 to 1550nm including IR optimized objective lenses with selectable magnifications from 2.5x, 5x, 10x, 20x, 63x, 100x.

- The high resolution InGaAs-camera guarantees best image resolution and highest contrast images.

- The IR optimized illumination path can be switched to incident and/or transmitted light.

- A combination of IR & visible light inspection is supported.

- The autofocus can be chosen between real-time laser autofocus or the highly intelligent fast image autofocus

- The best-in-class technology ensures worldwide leading edge performance regarding accuracy, repeatability and throughput.

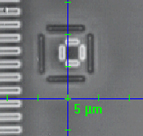

CD & Overlay Measurement

The combination of a high resolution objective lens (up to 100x) and our powerful NanoStar software solution guarantees the best available measurement accuracy with sub-micron repeatability for CD and overlay measurements. Our systems feature a unique combination of visible and infrared illumination in order to deliver optimized results for structures on the top, and the bottom, and inside the substrate.

Overlay top-to-bottom

Products

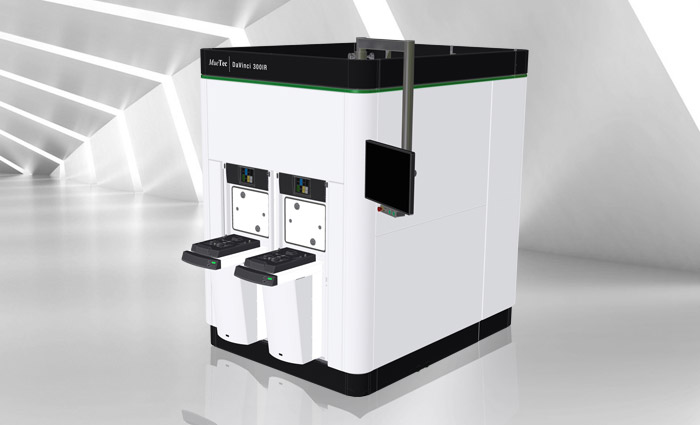

DaVinci 200IR + 300IR

200mm MEMS inspection and metrology system (SMIF)Show details

Typical Applications

Sealing Inspection after bonding

(eutectic bonding or glass frit bonding)

Device Inspection after bonding

Overlay Metrology after bonding

Critical Dimension Metrology after bonding

Features

Best inclassIR image quality with wafelengths of up to 1500nm

Flexible handling (backside vacuum, flipping, edge-vacuum) for MEMS specific wafers

Combined reflected & transmitted light illumination modes

SECS/GEM

IRIS2100

200mm MEMS inspection and metrology system (open cassette)Show details

Typical Applications

MEMS Sealing Inspection

MEMS Device Inspection

Overlay/CD Metrology

Defect Review

Features

Best IR image quality

Flexible handling (backside vacuum, flipping, edge-vacuum) for MEMS specific wafers

Combined reflected & transmitted light illumination modes

SECS/GEM