Integrated circuits are mostly built on Silicon wafer material. Many different devices - like transistors, diodes or capacitors - are connected by multiple interconnect layers. Thin film and furnace processes are followed by masking steps which consist of a structuring lithography process and a subsequnet etch process. These sequencies require intensive metrology processes to keep the process in a certain window. MueTec offers a wide variety of metrology and measurement processes, like:

- Critical Dimension or CD Measurement like active area, gate length or contact diameter

- Modern manufacturing processes consist of 30 and more masking levels which have to be perfect in Overlay

- Film thickness measurement of transparent films like Oxide, Nitride or Photo resist

- Defects and their reduction play a important role in the overall profitability of a manufacturing line. Therefore Defect Inspection and Review are important tools for engineers to increase yield.

- Since Silicon is transparent to IR radiation - we are utilizing this optical band for Infrared Inspection & Measurement to look deep into the wafer structure without damaging it.

Get in Touch

Reasons to Choose MueTec

Since decades we are listening to your manufacturing challenges and, together with you, find solutions to solve them successfully. You are invited to benefit from our accumulated know how that translates into tools, software algorithms and application support.

The installed base of our tools reaches from volume semiconductor manufacturers to mask shops and research institutes. We installed and service hundreds of tools all around the world. The satisfaction of our customers drives our motivation to exceed their expectations.

We are proud to provide the flexibility to adopt our solutions to your individual requirements. All of us at MueTec understand that one size does not fit all and we are proud of our ability to adopt to your special needs in a fast and competent fashion.

Our existing customers value the robustness of our tools, many of them being in use for 15 years or longer. All of our tools are designed and manufactured in Germany with highest quality standards.

Our Mission

MueTec serves the semiconductor equipment industry as well as a number of other, closely related industries. Our systems, services and software algorithms help nanoelectronics manufacturers manage yield and minimize waste throughout their manufacturing process, from research and development to final mass production.

- Cost-effective solutions

- Your metrology and inspection specialist

- Installed base of more than 250 systems

- Local service and maintenance from certified technicians

Best Solutions for Si-Wafer

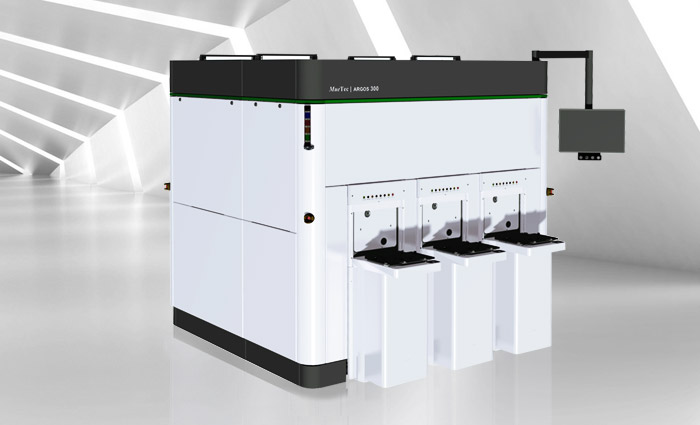

Argos 300

200mm/300mm Wafer Macro Defect InspectionShow details

Key Features

300 mm FOUP based handling

Data acquisition perfectly balanced to mechanical movements

Simultaneous bright- and darkfield front and backside inspection

Modular design with 1 – 3 process chambers, depending on throughput requirements

No recipe required for ease of use:

Enables productivity gains through minimum recipe customization

Ideal for fabs and packaging areas with many different devices & die sizes

No knowledge about geometry and physical parameters needed

Die layout data is not necessary

Recognition of active die area and EBR zone

Different sensitivities for different wafer areas

Avoiding false positives at zone transitions

Automatic adjustment of light intensity

Reflectivity of inspected layer is not necessary

Automatic defect recognition parameters by adaptive software algorithm

MT3000

Fully automated metrology and inspection system (open cassette)Show details

Typical Applications

CD

Overlay

Film Thickness

Defect Inspection

Defect Review

Features

VIS, UV

Simultaneous wafer handling 75 - 200mm

SECS/GEM

MT5500 / MT7500

Large area metrology and inspection system

Show details

Features

CD > 0,3 micron

contact holes > 0,3 micron

chrome and phase shift

resist on chrome

line edge roughness

substrate size up to 550mm x 550mm

DUV, 248nm; UV 365nm

DUV, UV, VIS

reflected and transmitted light

Substrates

large area scales

plastic electronics

glass scales

special customized solutions

Individual Inquiry

MT2010

Fully automated metrology and inspection system (open cassette)Show details

The MT2010 is designed for high precision defect inspection and metrology tasks on masks up to 6”. The system uses different illumination sources in transmitted and reflected light such as visible, I-line (365nm) and DUV (248nm).

MT2010 comes with laser autofocus and an anti-vibration isolating base frame with light tower.