MueTec provides a comprehensive range of automated optical inspection (AOI) systems for various applications in the wafer and photomask industry, including CD (Critical Dimension) and Overlay Metrology, Defect Inspection, Defect Review and Film Thickness Measurement. These defect inspection and metrology equipment solutions are designed to support fabs expedite their development and production ramp cycles, to achieve higher semiconductor die yields and to improve return on invest.

Our products are also used in related industries, including wafer manufacturing, photomask manufacturing, MEMS and LED manufacturing and general materials research. Our portfolio ranges from stand-alone microscopes and semi-automated systems all the way to fully-automated products and systems. We support wafer sizes from 50.8 mm to 300 mm and mask sizes up to 750 mm. We invite you to visit sections of our website specific to your company’s metrology and inspection needs.

Products for Metrology & Inspection

Spector-A

Fully automated mask metrology and inspection systemShow details

Typical Applications

CD

Defect Inspection

Features

Mask sizes up to 8“ by 8“

Robot handling

SECS/GEM

VIS, UV

Also available as semi-automated system with manual mask loading (Spector-M)

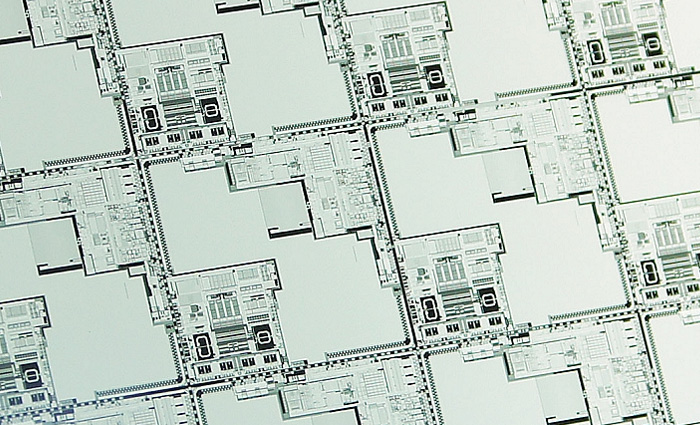

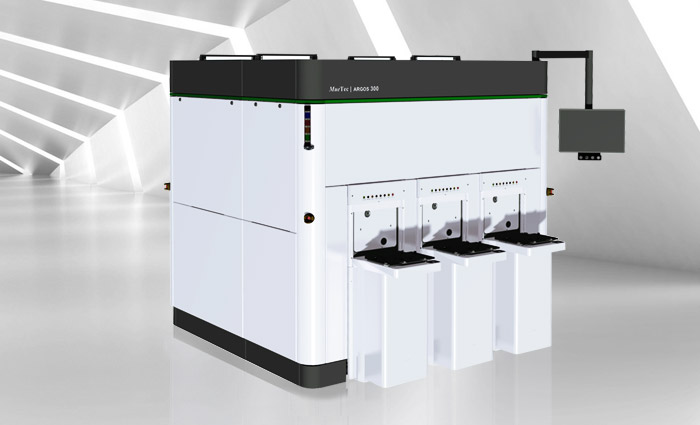

Argos 300

200mm/300mm Wafer Macro Defect InspectionShow details

Key Features

300 mm FOUP based handling

Data acquisition perfectly balanced to mechanical movements

Simultaneous bright- and darkfield front and backside inspection

Modular design with 1 – 3 process chambers, depending on throughput requirements

No recipe required for ease of use:

Enables productivity gains through minimum recipe customization

Ideal for fabs and packaging areas with many different devices & die sizes

No knowledge about geometry and physical parameters needed

Die layout data is not necessary

Recognition of active die area and EBR zone

Different sensitivities for different wafer areas

Avoiding false positives at zone transitions

Automatic adjustment of light intensity

Reflectivity of inspected layer is not necessary

Automatic defect recognition parameters by adaptive software algorithm

MT3000

Fully automated metrology and inspection system (open cassette)Show details

Typical Applications

CD

Overlay

Film Thickness

Defect Inspection

Defect Review

Features

VIS, UV

Simultaneous wafer handling 75 - 200mm

SECS/GEM

MT2010

Fully automated metrology and inspection system (open cassette)Show details

The MT2010 is designed for high precision defect inspection and metrology tasks on masks up to 6”. The system uses different illumination sources in transmitted and reflected light such as visible, I-line (365nm) and DUV (248nm).

MT2010 comes with laser autofocus and an anti-vibration isolating base frame with light tower.

MT5500 / MT7500

Large area metrology and inspection system

Show details

Features

CD > 0,3 micron

contact holes > 0,3 micron

chrome and phase shift

resist on chrome

line edge roughness

substrate size up to 550mm x 550mm

DUV, 248nm; UV 365nm

DUV, UV, VIS

reflected and transmitted light

Substrates

large area scales

plastic electronics

glass scales

special customized solutions

Individual Inquiry