High Throuput Macro Defect Inspection

MueTec’s Macro Defect Inspection products are designed for customers with many different wafer types. The system is easy to operate and does not require to write any recipes. It also enables 100% inspection of all wafer during the process of lithography with a throughput that is equal to, or faster that of a lithography cluster. In consequence, we enable our customers to move from sample inspection to inspection of all wafer and from manual inspection by operators to a statistically reliable, automated inspection process. Our tools can easily be setup without using much floor space. Low acquisition and operating costs guarantee a fast return on invest.

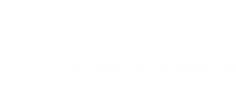

Here you can see an example of resist failure and an example resist streaks at lithography.

SIGNIFICANT ADVANTAGES

Enabling 100% wafer inspection at lithography

- Throughput 200 wafer per hour

- No recipe required for ease of use

- Replaces manual inspection

- Simulaneous wafer frontside and backside inspection

- Highly cost effective solution for fast return on inves

Products

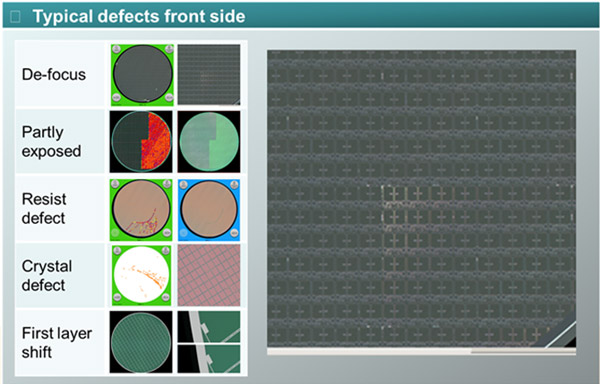

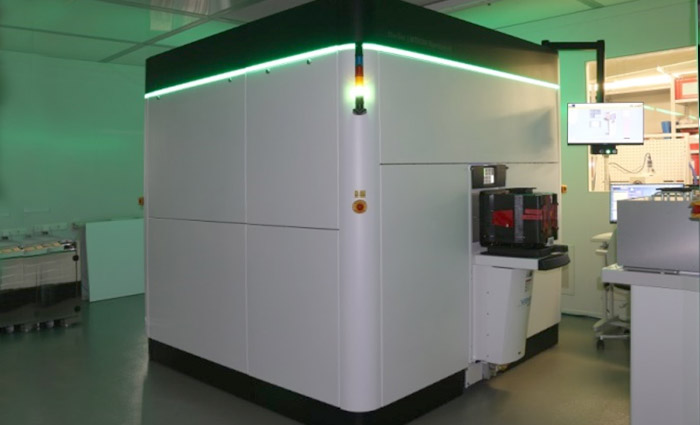

Rembrandt 200 / 300

200mm MEMS inspection and metrology system (SMIF)Show details

Typical Applications

Macro defect inspection of 200mm and 300mm wafer

Features

200mm SMIF or 300 mm FOUP based handling

Data acquisition perfectly balanced to mechanical movements

Illumination: Bright and darkfield, LED based

Black/white and colored image of sample

Modular system architecture results in small footprint

Design allows addition of 3rd module and 4th FOUP

Throughput optimized & balanced system integration avoids bottlenecks

MT3000

Fully automated metrology and inspection system (open cassette)Show details

Typical Applications

CD

Overlay

Film Thickness

Defect Inspection

Defect Review

Features

VIS, UV

Simultaneous wafer handling 75 - 200mm

SECS/GEM

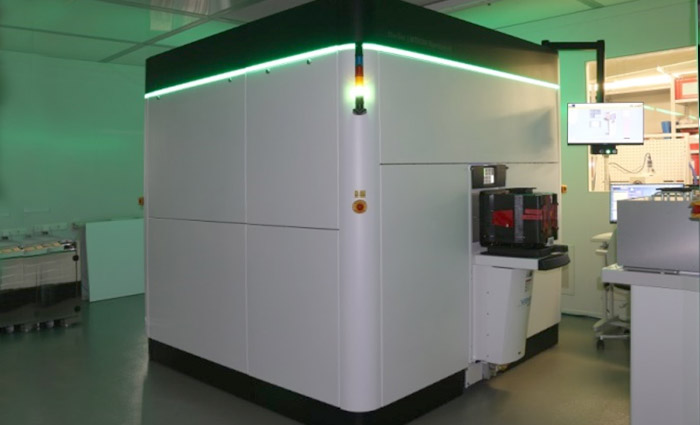

High Resolution Macro Defect Inspection

For customers with higher resolution requirements, MueTec provides a high resolution macro defect inspection solution down to 1μm.

SIGNIFICANT ADVANTAGES

- Recipe-less algorithm: Ideal for wafer fabs with many different product types

- Cost effective - replaces manual inspection

- Two simultaneous illumination modes (bright field, dark field)

- Throughput of 50 wph at 2µm/pixel resolution

- 300mm FOUP or 200mm SMIF version available

Products

Rembrandt 200 / 300

200mm MEMS inspection and metrology system (SMIF)Show details

Typical Applications

Macro defect inspection of 200mm and 300mm wafer

Features

200mm SMIF or 300 mm FOUP based handling

Data acquisition perfectly balanced to mechanical movements

Illumination: Bright and darkfield, LED based

Black/white and colored image of sample

Modular system architecture results in small footprint

Design allows addition of 3rd module and 4th FOUP

Throughput optimized & balanced system integration avoids bottlenecks